Ho Bopa Bokamoso: Karolo ea ho Machining Likarolo tsa CNC le Likarolo tsa Brass tsa CNC ho Indasteri ea Sejoale-joale

Boqapi bo nepahetseng bo nang le Lisebelisoa tsa Brass CNC

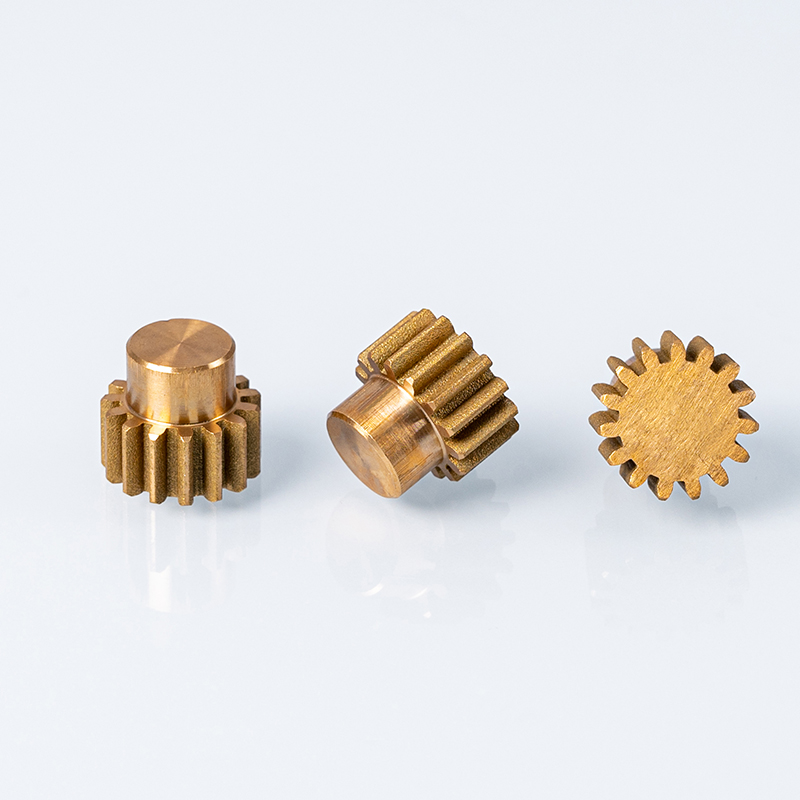

Bohareng ba phetoho ena ho na le boqapi bo nepahetseng, bo ntlafalitsoeng ka lisebelisoa tsa koporo tsa CNC.Mosebetsi ona o rarahaneng o kopanya matla a theknoloji ea CNC le litšobotsi tse ikhethang tsa koporo.Phello e bile efe?Likarolo tse ikhethang tsa CNC tsa koporo tse lulang li kopana le ho feta maemo a thata a indasteri.Likarolo tse fetolang koporo li entsoe ka boqhetseke, li bonts'a tsebo ea ho sebetsa ka nepo.

Likarolo tsa Brass tsa CNC: Phetoho ea Paradigm ho Indasteri ea Sejoale-joale

Likarolo tsa CNC tsa koporo li entsoe ka mokhoa o nepahetseng ka ho fetesisa, li etsa hore e be tsa bohlokoa indastering ea sejoale-joale.Katleho ea indasteri e itšetlehile ka likarolo tsa koporo tsa CNC, tse khetholloang ka thepa e ikhethang e kang ho hanyetsa kutu le motlakase oa motlakase.Ha tlhoko ea likarolo tse rarahaneng le tse rarahaneng e ntse e hola, likarolo tsa koporo tsa CNC li eme e le bopaki ba bokhabane ba boenjiniere.

Bokhabane ba Brass: Ho Lekola Likaroloana tsa Brass tsa Machining

Likarolo tsa koporo tsa machining li kenyelletsa symphony ea mekhoa ea ho itšeha, ea ho bopa le ea ho qeta.Mantsoe a indasteri a atoloha ho kenyelletsa mantsoe a kang "ho seha likhoele," "ho phunya" le "knurling."Mekhoa ena e sebelisoa ka bokhabane ho hlahisa likarolo tse rarahaneng tse tsejoang ka ho tšoarella ha tsona le bokhabane ba tsona.

Brass in Indasteri: Kopano ea Setso le Boqapi

Ho kopanngoa ha koporo indastering ea sejoale-joale ho koala lekhalo lipakeng tsa moetlo le boqapi.Thepa ea Brass, e kopantsoeng le boenjiniere bo nepahetseng, e netefatsa hore likarolo tsa koporo tsa CNC le likarolo tsa koporo tsa machining li lula li le ka pele ho lits'ebetso tse tsoetseng pele.Brass CNC e fetotsoe likarolo le machining a nepahetseng a fana ka motsoako o ke keng oa bapisoa oa ts'epahalo, ts'ebetso le ho feto-fetoha ha maemo.

Ho Rala Bokamoso: Ho Betla Tsela Pele

Ha indasteri e ntse e tsoela pele, bohlokoa ba ho lokisa likarolo tsa CNC le likarolo tsa koporo tsa CNC ho bopeng bokamoso bo bonahala le ho feta.Ho lelekisa ho nepahala, ho tloha ho likarolo tsa koporo tsa CNC ho ea ho likarolo tse rarahaneng tsa koporo, ke bopaki ba ho phehella bokhabane ho sa feleng.

Qetellong, bohlokoa ba likarolo tsena bo tla tsoela pele ho khothaletsa bokhabane le ho hlakisa maemo a indasteri bocha.

Kopo:

Indasteri ea 3C, mokhabiso oa mabone, lisebelisoa tsa motlakase, likarolo tsa koloi, likarolo tsa thepa ea ka tlung, lisebelisoa tsa motlakase, lisebelisoa tsa bongaka, lisebelisoa tse bohlale tsa boiketsetso, likarolo tse ling tsa tšepe.