CNC machining ka likarolo tsa koporo bakeng sa bongaka

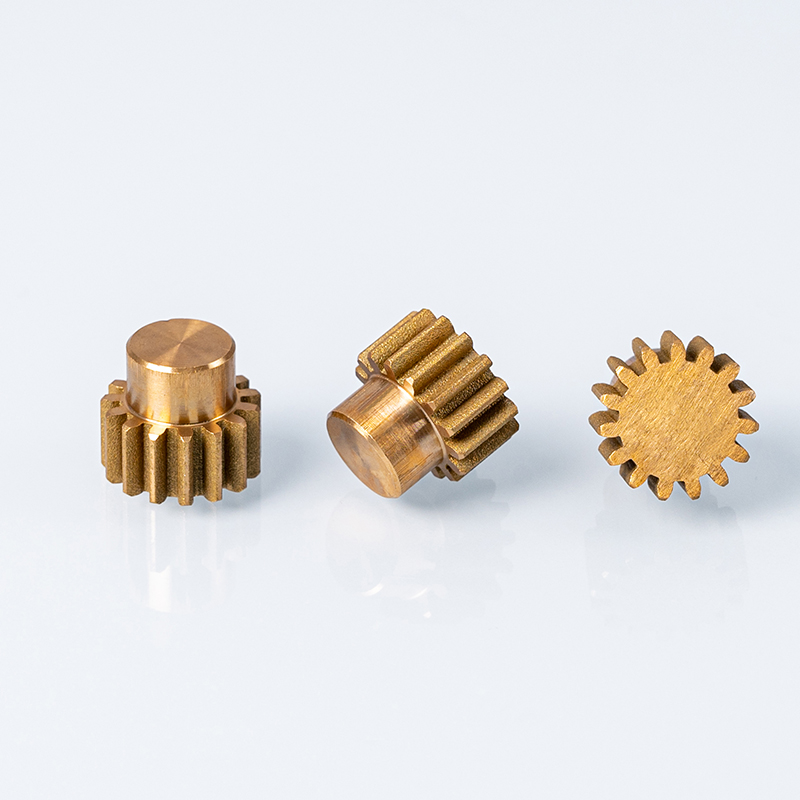

Tlhaloso ea likarolo tsa mochini oa CNC tse nang le Copper Material

Koporo e boetse ha e na makenete ebile ha e chese, e etsa hore e loketse ho sebelisoa lisebelisoa tsa bongaka tse pepesehileng maqhubu a motlakase kapa masimo a matla a phahameng.Koporo e boetse e hana ho bola, e leng se etsang hore e be khetho e ntle bakeng sa lisebelisoa tsa bongaka tse pepesehileng metsing kapa lino tse ling.CNC machining ka koporo e lumella ho hlahisa likarolo tse rarahaneng, tse rarahaneng tse nang le tekanyo e phahameng ea ho nepahala le ho nepahala.Likarolo tsa koporo li ka etsoa ho latela litlhaloso le mamello, ho netefatsa hore lisebelisoa tsa bongaka li bolokehile ebile lia sebetsa.

1. Boitsebiso ba Koporo: C110 (99.9% Koporo)

2. Mokhoa: CNC Machining

3. Mamello: +/-0.01mm

4. Qetella: Tlhaho 5. Kopo: E sebelisoa ho elektronike, motlakase, mabone le liindasteri tse ling.

Monyetla oa CNC machining Copper

CNC machining koporo e fana ka melemo e mengata, joalo ka ho nepahala le ho nepahala ho phahameng, karo-karolelano e matla ea boima ba 'mele, mocheso o motle oa mocheso le motlakase, ho hanyetsa kutu ha ho bapisoa le litšepe tse ling, botsitso ba sebopeho holim'a mocheso o pharalletseng, nako ea mochini e fokotsehileng ka lebaka la eona. ho ba bonolo le bonolo ba machaena.

1. Matla a phahameng le ho tšoarella - Koporo ke thepa e tšoarellang ka ho fetisisa 'me e khona ho mamella mocheso o phahameng, khatello le ho apara.Sena se etsa hore e be khetho e ntle haholo bakeng sa lits'ebetso tsa machining tsa CNC, kaha e ka sebelisoa lits'ebetsong tse fapaneng mme e khona ho mamella mathata a ts'ebetso ea ho pheta-pheta, e nepahetseng haholo.

2. Ts'ebetso e ntle ea mocheso oa mocheso - Copper e ntle haholo ea mocheso oa mocheso o etsa hore e be o loketseng bakeng sa lisebelisoa tsa mochine oa CNC tse hlokang ho itšeha le ho cheka ka mokhoa o nepahetseng.Sena se tiisa hore sehlahisoa se felileng se tla ba le boemo bo phahameng ka ho fetisisa ba ho nepahala le ho nepahala.

3. Motlakase o phahameng oa motlakase - Karolo ena e etsa hore koporo e be thepa e loketseng bakeng sa ts'ebetso ea machining ea CNC e hlokang likhoele tsa motlakase kapa likaroloana.

4. Theko e tlaase - Koporo hangata e theko e tlaase ho feta litšepe tse ling, e leng se etsang hore e be khetho e phethahetseng bakeng sa merero ea machining ea CNC e hlokang palo e kholo ea likarolo kapa likaroloana.

5. Ho bonolo ho sebetsa - Koporo ke ntho e bonolo ho sebetsa le eona, e lumellang tlhahiso e potlakileng le ho nepahala ho hoholo.

Joang Koporo ka likarolo tsa machining tsa CNC

Likarolo tsa koporo tsa CNC li kenyelletsa tšebeliso ea lisebelisoa tse nepahetseng tsa ho itšeha joalo ka limilone tsa ho qetela ho tlosa thepa ho tloha ho workpiece ho latela tsela e hlophisitsoeng.Lenaneo la machining la CNC le etsoa ka software e thusoang ke komporo (CAD) ebe e fetisetsoa mochining ka khoutu ea G, e o lumellang ho sebetsana le motsamao o mong le o mong ka ho latellana.Likarolo tsa koporo li ka chekoa, tsa siloa kapa tsa fetoloa ho latela kopo.Mekelikeli ea tšepe e boetse e sebelisoa hangata nakong ea ts'ebetso ea mochini oa CNC, haholo ha o sebetsana le litšepe tse thata joalo ka koporo tse hlokang lubrication e eketsehileng.

CNC machining likarolo tsa koporo ke mokhoa oa ho sebelisa mechine e laoloang ke linomoro tsa khomphutha (CNC) ho bopa lisebelisoa tsa koporo.Koporo e sebelisoa mefuteng e fapaneng ea lits'ebetso tsa CNC ho kenyelletsa prototyping, hlobo, lisebelisoa le likarolo tsa tšebeliso ea ho qetela.

CNC machining koporo e hloka ts'ebeliso ea software e khethehileng le mechini ea CNC e nang le lisebelisoa tse nepahetseng ho seha le ho bopa thepa ka nepo.Ts'ebetso e qala ka ho theha mohlala oa 3D oa karolo e lakatsehang lenaneong la CAD.Joale mohlala oa 3D o fetoloa tsela ea lisebelisoa, e leng sete ea litaelo tse hlophisang mochine oa CNC ho hlahisa sebopeho se lakatsehang.

Joale mochini oa CNC o laeloa lisebelisoa tse loketseng, joalo ka mabili a ho qetela le likotoana tsa ho phunya, ebe thepa e kenngoa mochining.Thepa e ntan'o etsoa mochine ho latela tsela ea sesebelisoa e hlophisitsoeng 'me sebopeho se lakatsehang se hlahisoa.Kamora hore ts'ebetso ea mochini e phetheloe, karolo e hlahlojoa ho netefatsa hore e kopana le litlhaloso.Haeba ho hlokahala, karolo e phethoa ka mekhoa e fapaneng ea ho lokisa ka mor'a ho sebetsa joalo ka ho buffing le ho bentsa.

Ke likarolo life tsa machining tsa CNC tse ka li sebelisang bakeng sa Copper

Likarolo tsa koporo tsa CNC tsa machining li ka sebelisoa bakeng sa lits'ebetso tse fapaneng, ho kenyeletsoa likarolo tsa elektronike le lihokelo, likarolo tsa koloi tse nepahetseng haholo, lisebelisoa tsa sefofane, lisebelisoa tsa bongaka, likopano tse rarahaneng tsa mochini le tse ling.Likarolo tse entsoeng ka mochini oa Copper CNC hangata li tlatsitsoe ka litšepe tse ling ho ntlafatsa conductivity kapa ho roala ho hanyetsa.

Likarolo tsa koporo tsa CNC li ka sebelisoa bakeng sa lits'ebetso tse fapaneng, ho kenyeletsoa likhokahanyo tsa motlakase, matlo a makoloi, li-exchangers tsa mocheso, likarolo tsa matla a mokelikeli, likarolo tsa meralo le likarolo tsa mekhabiso.Likarolo tsa koporo li loketse machining a CNC ka lebaka la ho ts'oaroa ha motlakase le mocheso o phahameng, le khanyetso ea eona e ntle ea kutu.CNC machining koporo e ka boela ea sebelisoa ho theha libopeho tse rarahaneng le likarolo tse nang le mamello e nepahetseng.

Ke mofuta ofe oa phekolo ea holim'a metsi o loketseng likarolo tsa machining tsa CNC tsa Copper

Phekolo e nepahetseng ka ho fetesisa ea holim'a likarolo tsa koporo ea CNC ke anodizing.Anodizing ke ts'ebetso e kenyelletsang electro ho phekola tšepe ka lik'hemik'hale le ho etsa lera la oxide holim'a thepa e eketsang ho hanyetsa ho apara le tšireletso ea ho senya.E ka boela ea sebelisoa ho fana ka likhabiso tse khabisitsoeng tse kang mebala e khanyang, qetello ea matte kapa lithane tse khanyang.

Li-alloys tsa koporo hangata li alafshoa ka nickel plating e se nang electroless, anodizing le passivation ho sireletsa bokaholimo hore bo se ke ba bola le ho senyeha.Mekhoa ena e boetse e sebelisetsoa ho ntlafatsa aesthetics ea karolo.

Kopo:

Indasteri ea 3C, mokhabiso oa mabone, lisebelisoa tsa motlakase, likarolo tsa koloi, likarolo tsa thepa ea ka tlung, lisebelisoa tsa motlakase, lisebelisoa tsa bongaka, lisebelisoa tse bohlale tsa boiketsetso, likarolo tse ling tsa tšepe.