Ke lisebelisoa tsa mofuta ofe tse khethehileng tse tla sebelisoa likarolong tse entsoeng ka mochini oa oli le khase ea CNC?

Likarolo tse entsoeng ka mochini oa CNC tse sebelisoang indastering ea oli le khase li hloka lisebelisoa tse khethehileng tse ka mamellang khatello e phahameng, mocheso o phahameng le tikoloho e senyang.Mona ke tse ling tsa lisebelisoa tse ikhethileng tse sebelisoang hangata likarolong tse entsoeng ka oli le khase tsa CNC hammoho le likhoutu tsa tsona:

Ha u khetha thepa bakeng sa likarolo tsa mochini oa oli le khase ea CNC, ho bohlokoa ho nahana ka litlhoko tse ikhethileng tsa ts'ebeliso, joalo ka khatello, mocheso le ho hanyetsa kutu.Boitsebiso bo tlameha ho khethoa ka hloko ho netefatsa hore karolo e ka mamella meroalo e lebeletsoeng le maemo a tikoloho le ho fana ka ts'ebetso e ka tšeptjoang holim'a bophelo ba tšebeletso bo reriloeng.

| Oli e Tloaelehileng Boitsebiso | Khoutu ea thepa ea oli |

| Nickel Alloy | LILEMO 925,INCONEL 718(120,125,150,160 KSI),NITRONIC 50HS,MONEL K500 |

| Ts'epe e sa beng le mabali | 9CR,13CR,SUPER 13CR,410SSTANN,15-5PH H1025,17-4PH(H900/H1025/H1075/H1150) |

| Non-magnetic Stainless Steel | 15-15LC,P530, Datalloy 2 |

| Alloy Steel | S-7,8620,SAE 5210,4140,4145H MOD,4330V,4340 |

| Motsoako oa Koporo | AMPC 45,TOUGHMET,BRASS C36000,BRASS C26000,BeCu C17200,C17300 |

| Motsoako oa Titanium | CP TITANIUM GR.4,Ti-6AI-4V, |

| Li-alloys tsa Cobalt-base | STELLITE 6,MP35N |

Ke lisebelisoa tsa mofuta ofe tse khethehileng tse tla sebelisoa likarolong tse entsoeng ka mochini oa oli le khase ea CNC?

Likhoele tse khethehileng tse sebelisoang likarolong tse entsoeng ka oli le khase tsa CNC li tlameha ho etsoa ho fihlela litlhoko tse khethehileng tsa kopo, joalo ka khatello e phahameng, mocheso o phahameng le maemo a thata a tikoloho.Likhoele tse sebelisoang haholo indastering ea oli le khase li kenyelletsa:

Hlahisa karabo bocha

Ha u khetha khoele bakeng sa likarolo tse entsoeng ka oli le khase tsa CNC, ho bohlokoa ho nahana ka litlhoko tse khethehileng tsa kopo le ho khetha khoele e ka mamellang meroalo e lebelletsoeng le maemo a tikoloho.Hape ke habohlokoa ho etsa bonnete ba hore khoele e etsoa ho latela litekanyetso le litlhaloso tse nepahetseng ho netefatsa hore li lumellana le likarolo tse ling tsa tsamaiso.

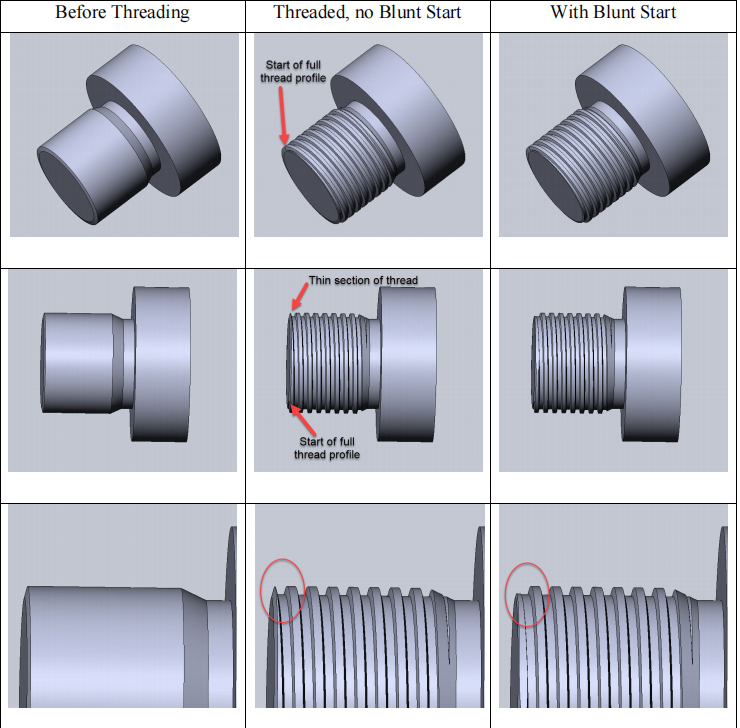

Mona ke tse ling tse khethehileng bakeng sa litšupiso:

| Mofuta oa Khoele ea Oli | Kalafo e Khethehileng ea Bokaholimo ba Oli |

| Lethathamo la lintlha tsa UNRC | Vacuum electron beam welding |

| Lethathamo la lintlha tsa UNRF | Flame sprayed (HOVF) nickel tungsten carbide |

| TC Khoele | Ho roala Koporo |

| Khoele ea API | HVAF (High Velocity Air Fuel) |

| Khoele ea Spiralock | HVOF (High Velocity Oxy-Fuel) |

| Sekwere Khoele |

|

| Buttress Thread |

|

| Khoele e Khethehileng ea Buttress |

|

| Khoele ea OTIS SLB |

|

| Lethathamo la lintlha tsa NPT |

|

| Rp(PS)Khoele |

|

| RC(PT)Khoele |

Ke mofuta ofe oa kalafo e khethehileng ea holim'a metsi e tla sebelisoa likarolong tse entsoeng ka mochini oa oli le khase ea CNC?

Phekolo ea bokaholimo ba likarolo tsa mochini oa CNC ke karolo ea bohlokoa ea ho netefatsa ts'ebetso ea tsona, ho tšoarella le ho phela halelele maemong a thata a indasteri ea oli le khase.Ho na le mefuta e 'maloa ea kalafo ea holim'a metsi e sebelisoang hangata indastering ena, ho kenyelletsa:

Ho bohlokoa ho khetha kalafo e nepahetseng ea holim'a metsi ho latela ts'ebeliso e khethehileng le maemo a ts'ebetso ea likarolo tsa mochini oa CNC indastering ea oli le khase.Sena se tla etsa bonnete ba hore likarolo li khona ho mamella maemo a thata le ho etsa mosebetsi oa tsona o reriloeng ka katleho le ka katleho.

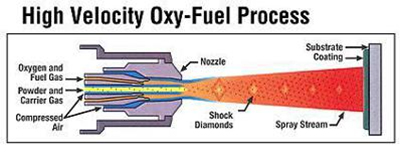

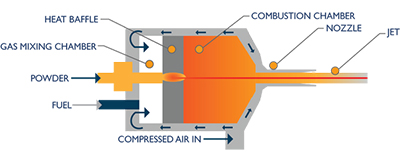

HVAF (High-Velocity Air Fuel) &HVOF (High-Velocity Oxygen Fuel)

HVAF (High-Velocity Air Fuel) le HVOF (High-Velocity Oxygen Fuel) ke mekhoa e 'meli e tsoetseng pele ea ho koahela holim'a metsi e sebelisoang hangata indastering ea oli le khase.Mekhoa ena e kenyelletsa ho futhumatsa thepa e phofshoana le ho e potlakisa ka lebelo le phahameng pele e e beha holim'a karolo e entsoeng ka mochine.Lebelo le phahameng la likaroloana tsa phofo le lebisa ho lesela le teteaneng le le tiileng le fanang ka khanyetso e phahameng ea ho apara, khoholeho le ho bola.

HVOF

HVAF

Liaparo tsa HVAF le HVOF li ka sebelisoa ho ntlafatsa ts'ebetso le nako ea bophelo ea likarolo tsa mochini oa CNC indastering ea oli le khase.Melemo e meng ea liphahlo tsa HVAF le HVOF li kenyelletsa:

1.Corrosion Resistance: Liaparo tsa HVAF le HVOF li ka fana ka khanyetso e ntle ea kutu ho likarolo tse entsoeng ka mochini tse sebelisoang libakeng tse thata tsa indasteri ea oli le khase.Liaparo tsena li ka sireletsa bokaholimo ba likarolo hore li se ke tsa pepesehela lik'hemik'hale tse senyang, mocheso o phahameng le likhatello tse phahameng.

2.Apara Resistance: Liaparo tsa HVAF le HVOF li ka fana ka khanyetso e phahameng ea ho roala ho likarolo tsa mochini tse sebelisoang indastering ea oli le khase.Liaparo tsena li ka sireletsa bokaholimo ba likarolo hore li se ke tsa roala ka lebaka la ho senyeha, tšusumetso le khoholeho.

3.Lubricity e Ntlafalitsoeng: Liaparo tsa HVAF le HVOF li ka ntlafatsa mafura a likarolo tse entsoeng ka mochini tse sebelisoang indastering ea oli le khase.Liaparo tsena li ka fokotsa likhohlano lipakeng tsa likarolo tse tsamaeang, tse ka lebisang ho ntlafatseng ts'ebetso le ho fokotsa ho roala.

4.Thermal Resistance: Liaparo tsa HVAF le HVOF li ka fana ka khanyetso e ntle ea mocheso ho likarolo tse entsoeng ka mochini tse sebelisoang indastering ea oli le khase.Liaparo tsena li ka sireletsa likarolo ho tloha mocheso oa mocheso le libaesekele tsa mocheso, tse ka lebisang ho phunyeha le ho hlōleha.

5.Ka kakaretso, liphahlo tsa HVAF le HVOF ke mahlale a holimo a holimo a ka fanang ka tšireletso e phahameng ho likarolo tsa mochini oa CNC tse sebelisoang indastering ea oli le khase.Liaparo tsena li ka ntlafatsa ts'ebetso, ho tšoarella le nako ea bophelo ea likarolo, e leng se lebisang ho ntlafatseng ts'ebetso le ho fokotsa litšenyehelo tsa tlhokomelo.