Ho qala bokamoso: Karolo ea karolo ea CNC le CNC Brass likarolo tsa khoebo tsa kajeno

Tafole ea CraftsManight le Brass Cnc CNC e fetohileng likarolo

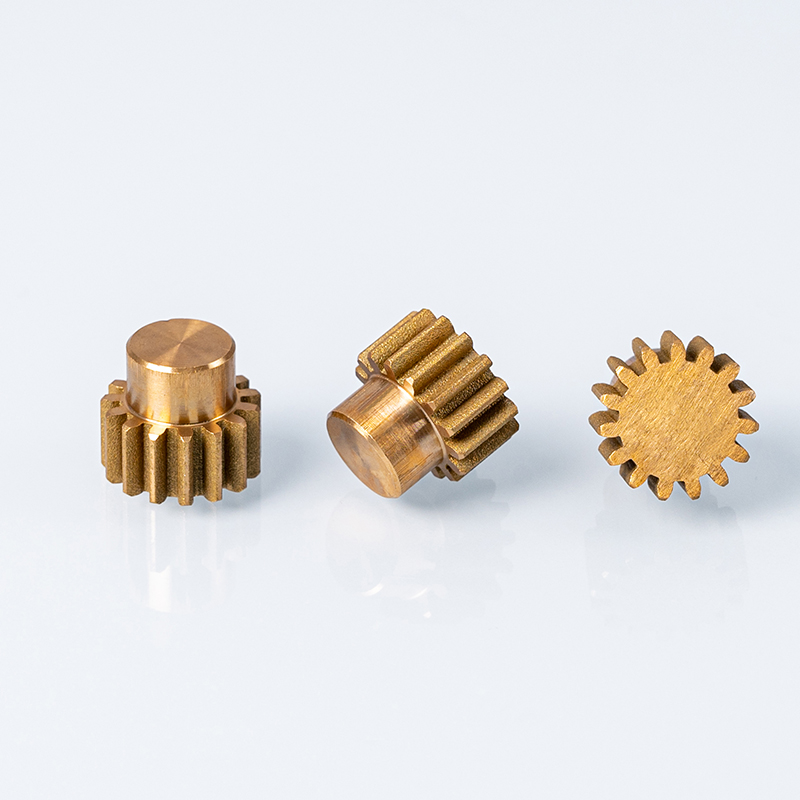

Puong ea phetoho ena e khahlapetsoang, e tlisitseng bophelong ka koporo ea koporo e fetohileng. Sebapali sena se rarahaneng se kopanya matla a CNC mahlale a nang le litšobotsi tse ikhethang tsa koporo. Phello? Likarolo tse ikhethang tsa CNC tsa Brass tse kopaneng le ho feta le ho feta litekanyetso tse thata tsa indasteri. Brass e silafatsa likarolo tse hlakileng, li bontša tsebo ea ho beoa ha ho na le tahi.

Likarolo tsa CNC Brass: Ho fetoloa ha pararigme indastering ea sejoale-joale

Likarolo tsa CNC tsa Cnc li sirelelitsoe ka nepo e kholo, li ba etsa ba bohlokoa indastering ea kajeno. Katleho ea indasteri e itšetleha ka likarolo tse ngata tsa CNC, e khetholloang ka maemo a ikhethang a kang ho hanyetsa le ts'ebetso ea motlakase. Ha litloaelo tsa likarolo tse rarahaneng le tse rarahaneng li ntse li eketseha, likarolo tsa cnc tsa sehlopha sa CNC e eme e le Testament ea Boenjiniere ho Bosholu.

Bophahamo ba koporo: Ho ithuta likarolo tsa Brass

Likarolo tsa koporo tsa Braning li kenyelletsa ho pefoe ke ho kuta, ho hlapa, le ho qeta mekhoa e mengata. Mantsoe a mantsoe a indasteri a a tsoa ho kenyelletsa mantsoe a kang "khoele ea ho kuta," ho cheka, "le" ho "kuta" le " Mekhoa ena e sebelisitse thepa ka hloko ho hlahisa likarolo tse rarahaneng tse tsejoang ka ho tšoarella ha tsona le boipiletso ba botle.

Brass indastering: Foution ea moetlo le boqapi

Khokahano ea koporo ea koporo litumelong tsa sejoale-joale li sesa maqhubu a setso le boitlamo. Mefuta ea Brans, e kopantsoeng le boenjiniere ba koporo, netefatsa hore likarolo tsa boenjiniere tsa CNC le lihlopha tsa koporo tsa mochini li lula li le ka pele ho lits'ebetso tse sehiloeng. Brass Cnc e ile ea fetohela likarolo le sepheo sa ho phela ha ho na le mekhoa e mengata ea ho tšepahala, boitšoaro le ho feto-fetoha.

Ho hlahisa bokamoso: ho ipolae tseleng e tlang pele

Joalokaha indasteri e ntse e tsoela pele, bohlokoa ba ho tsamaisa likarolo tsa CNC le CNC Brass ba ho hata bokamoso bo bonahala li letile haholo. Ho phehella ho nepahala, ho tsoa likarolo tsa CNC Brass ho fetola likarolo, ke Testamente ea ho lelekisa bokhabane bo sa feleng.

Qetellong, bohlokoa ba likarolo tsena bo tla tsoela pele ho tsosa maikutlo le ho fana ka litekanyetso tsa indasteri.

Kopo:

Litara tsa 3c, mokhabiso oa mabone, lisebelisoa tsa motlakase, likarolo tsa mantlha, sesebelisoa sa motlakase, lisebelisoa tsa bongaka tsa tšepe.