Likarolo tsa mochini tse bonolo tsa CNC

Lisebelisoa tse fumanehang

Tšepe e bonolo 1018 |1.1147 |c18 |280 grade 7M | 16Mn: AISI 1018 e bonolo / e tlaase ea carbon steel e na le tekanyo e ntle ea ductility, matla le ho tiea.E na le weldability e ntle haholo mme e nkuoa e le tšepe e ntle ka ho fetisisa bakeng sa likarolo tsa carburizing.

Tšepe ea carbon EN8/C45 |1.0503 |1045H |Fe:

Tšepe e bonolo S355J2 |1.0570 |1522H |Fe400:

Tšepe e bonolo 1045 |1.1191 |C45E |50C6:1045 ke tšepe ea k'habone e tiileng e mahareng e nang le matla a matle le thepa ea tšusumetso.E na le ts'ebeliso e ntle ea weldability sebakeng se chesang se kolobisitsoeng kapa se tloaelehileng. Joalo ka mosing, thepa ena e na le matla a tlase a thata.

Tšepe e Bonolo S235JR |1.0038 |1119 |Fe 410 WC:

Tšepe e bonolo A36 |1.025 |GP 240 GR |R44 |IS2062:A36 ke sehlopha se thehiloeng sa ASTM mme ke tšepe e atileng haholo ea sebopeho.Ke tšepe e sebelisoang ka ho fetisisa e bonolo le e chesang haholo.A36 e matla, e thata, e na le ductile, e ka bopeha ebile ea cheseha 'me E na le thepa e ntle e loketseng ho sila, ho phunya, ho tlanya, ho cheka le ho sebetsa ka machining.

Tšepe e bonolo S275JR |1.0044 |1518 |FE510:Steel grade S275JR ke tšepe e sa sebetseng ea alloy, 'me hangata e fanoa e le e chesang e kolobisitsoeng kapa ka sebopeho sa poleiti.Joalo ka tlhahiso ea tšepe e tlase ea khabone, S275 e fana ka matla a tlase, ka machinability e ntle, ductility mme e loketse lits'ebetso tsa welding.

Tšepe e bonolo hakae likarolong tsa machining tsa CNC

Tšepe e bonolo ke thepa e ntle haholo bakeng sa likarolo tsa machining tsa CNC kaha ho bonolo ho sebetsa ka eona ebile e ka phethoa ka boleng bo holimo.E boetse e batla e le theko e tlaase e etsa hore e be e loketseng bakeng sa prototyping e potlakileng le likarolo tsa tlhahiso ea likarolo tse tlase tsa mochini.E boetse e hanyetsana le ho bola, e leng se etsang hore e tšoanele likarolo tse tla pepesehela libaka tse thata kapa lik'hemik'hale.Tšepe e bonolo e matla ebile e tšoarella litšebeletsong tsa CNC, e leng se etsang hore e be khetho e ntle bakeng sa likarolo tsa mochini tse hlokang ho mamella meroalo e boima kapa ho taboha. "

Ke likarolo life tsa machining tsa CNC tse ka li sebelisang bakeng sa thepa ea tšepe e bonolo

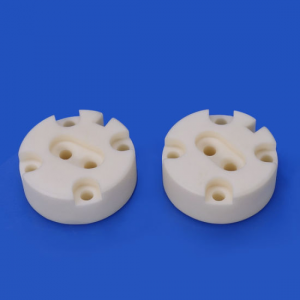

Tšepe e bonolo ke thepa e tsebahalang e sebelisoang likarolong tsa mochini tsa CNC.Likarolo tse tloaelehileng tse entsoeng ka tšepe e bonolo li kenyelletsa:

- Li-gears le li-splines

- Li-shafts

- Lihlahla le li-bearings

-Liphini le linotlolo

- Matlo le masakana

- Likopano

- Li-valve

- Li-fasteners

- Li-spacers le li-washer

-Fittings

- Liphoofolo"

Ke mofuta ofe oa kalafo ea holim'a metsi o loketseng likarolo tsa machining tsa CNC tsa thepa ea tšepe e bonolo

Bakeng sa likarolo tsa machining tsa CNC tsa thepa ea tšepe e bonolo, o ka khetha ho tsoa mefuteng e fapaneng ea kalafo ea holim'a metsi joalo ka electroplating,Black oxide, Zinc plating,Nickle plating,Chrome plating, ho roala phofo, penta, passivation,QPQ le polishing.Ho ipapisitsoe le litlhoko tsa ts'ebeliso le bokhabane, u ka khetha khetho e nepahetseng ka ho fetisisa ea kalafo ea holim'a metsi.