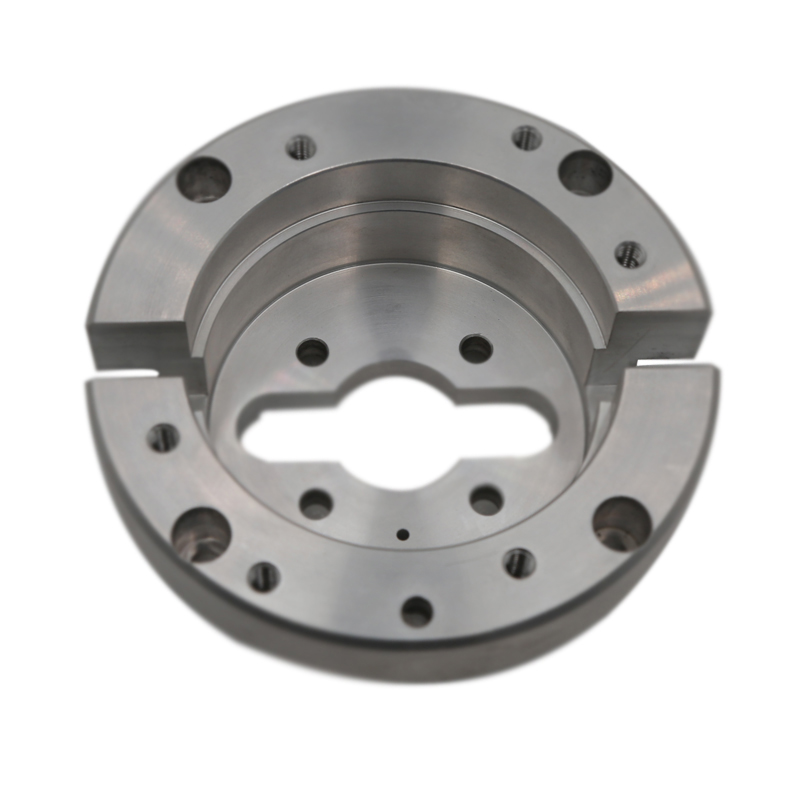

Likarolo tsa allow cnc karolo ea ho botsa

Lisebelisoa tse fumanehang

Alloy tšepe 1.7131 | 16mncr5: Alloy Steel 1.7131 e boetse e tsejoa e le 16mncr5 kapa 16mrcr5 (1.7131) ke sehlopha se phahameng se sebelisoang bakeng sa lits'ebetso tse fapaneng tsa boithimo. E tloaetse ho sebelisoa ka likerekeng, li-crankshafts, mabokose a gear, le likarolo tse ling tsa mochiniSeo se hloka hore ho be le thata ho thatafala le ho apara ho hanyetsa.

Alloy tšepe 4140| 1.2331 | En19| 42CRMO: Asi 4140 ke steel e tlase ea chromium le li-molybdentu li batla matla a ho elang. Hape e na le khanyetso e ntle ea sehlōhō. E sebelisoa haholo indasteri e mengata ka lebaka la thepa ea eona e ntlehali.

ALY STEEL 1.7225 | 42CRMO4:

Monyetla oa alloy steel

Alloy Steel 4340 | 1.6511 | 36Cnumimo4 | En24: ea tummeng ho ba thata le matla a eona a 4140 ke carbon e meholo e meholo ea alla. Ho ka batlisa mocheso o matla o matlafala ha o ntse o boloka ho tsitsipana, u apere khanyetso e matla le matla a Corrospioring.

Alloy tšepe 1215 | En1a:1215 ke moelelo oa khabone ea khase o nang le carbon e le ntho ea mantlha e alimileng. Hangata e bapisoa le khabone 1018 ka lebaka la ho tšoana ha likopo tsa bona, empa li na le liphapang tse ngata. 1215 tšepe e na le mochini o betere mme o ka boloka mamello e thata le ho qeta.

Phekolo ea mofuta ofe e loketseng likarolo tsa cnc mechini ea li-cnc tsa machining a thepa ea alloy Steel

Phekolo e tloaelehileng ka ho fetisisa bakeng sa likarolo tsa cnc machining ea li-cnc tsa tšepe li na le oxide e ntšo. Ena ke ts'ebetso e botsoalle e nang le tikoloho e fellang pheletsong e ntšo e nang le lehola le korotla. Litlhare tse ling li kenyelletsa tšilafalo ea Vibro, e ile ea thunya habohloko, le ho feta, ho penta, ho koataloa phofo le motlakase.