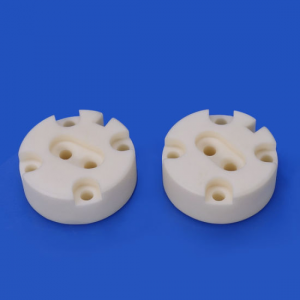

Li-ceramics tse tloaelehileng tsa CNC likarolo tsa machining tse nepahetseng

Tlhaloso ea CNC machining ceramics

CNC machining ea li-ceramics ke mokhoa oa ho seha le ho bopa lisebelisoa tsa ceramic ho sebelisa lisebelisoa tsa taolo ea linomoro tsa khomphutha (CNC).Ke ts'ebetso e nepahetseng haholo le e nepahetseng e ka sebelisoang ho hlahisa likarolo tse nang le mamello e thata le libopeho tse rarahaneng.CNC machining ea li-ceramics e ka sebelisoa ho theha likarolo tsa liindasteri tse fapaneng, ho kenyeletsoa sefofane, bongaka le likoloi.

Ts'ebetso ea mochini oa CNC e qala ka khetho ea thepa e nepahetseng ea ceramic bakeng sa ts'ebeliso e reriloeng.Ho latela ts'ebeliso, lisebelisoa tsa ceramic li ka tloha ho alumina, zirconia, le silicon nitride ho isa ho aluminium oxide le silicon carbide.Hang ha thepa e khethiloe, sebopeho se lakatsehang se kenngoa mochine oa CNC.Mochini oa CNC ebe o khaola thepa ea ceramic hantle hore e be sebopeho se batlang.

Hang ha thepa ea ceramic e khaotsoe, ebe e belisoa haeba ho hlokahala.Bakeng sa likarolo tse hlokang ho qeta holimo ho boreleli, hangata ho sebelisoa abrasive ea daemane.Mokhoa ona o boetse o sebelisetsoa ho hlahisa lintlha tse rarahaneng le libopeho tse rarahaneng.Ka mor'a hore thepa ea ceramic e benngoe, e ntan'o hlahlojoa ho netefatsa boleng.Qetellong, likaroloana li beoa tlas'a phekolo e eketsehileng e kang phekolo ea mocheso, phekolo ea holim'a metsi le litlolo.

Re tsepamisitse maikutlo ho hlahisoeng ha likarolo tsa aluminium tse sa sebetseng hantle tse nang le meaho e rarahaneng 'me re ikemiselitse ho fana ka likarolo tse nepahetseng le tse sa fetoheng ho bareki ba rona.Re tsoela pele ho tsetela lisebelisoa tse ncha tsa mochini oa CNC le basebetsi ba nang le boiphihlelo ho netefatsa hore sehlopha sa rona se boloka monyetla o matla oa tlholisano.Re boetse re ntse re ntlafatsa ts'ebetso ea mochini oa aluminium ho ntlafatsa ts'ebetso le boleng, le ho tsoela pele ho fihlela litlhoko tsa tlhahiso ea bareki.

Melemo ea CNC machining ceramics

1. Ho nepahala ho phahameng: Li-ceramics tsa CNC tsa machining li ka finyella ho nepahala ho phahameng ho sebetsa ka mokhoa o nepahetseng le ho pheta-pheta, tse ka finyellang litlhoko tsa likarolo tse rarahaneng tsa machining le machining a rarahaneng a holim'a metsi.

2. Katleho e phahameng: ka thuso ea mechine ea CNC, nako ea ts'ebetso ea likarolo tse rarahaneng tsa ceramic e khutsufatsoa haholo, 'me katleho ea tlhahiso e ntlafatsoa.

3. Theko e tlaase: CNC machining ceramics e ka fokotsa haholo litšenyehelo tsa ho sebetsa likarolo tsa ceramic, 'me ea ba le melemo e metle ea moruo.

4. Ho tšepahala ho phahameng: CNC machining ceramics e ka tiisa ho nepahala ha machining ea likarolo tsa ceramic le ho netefatsa ho lumellana ha likarolo.

5.Boleng bo botle ba holim'a metsi: CNC machining e ka ntlafatsa karolo ea holim'a likarolo tsa ceramic, 'me ea etsa hore likarolo tsa ceramic li be boreleli le tse ntle.

Joang li-ceramics likarolong tsa machining tsa CNC

CNC machining ea li-ceramics ke ts'ebetso e nepahetseng haholo e hlokang lisebelisoa le lisebelisoa tse khethehileng.Taba ea pele, faele ea CAD e entsoe kapa faele e teng ea CAD e fetotsoe ho hlalosa karolo ea geometry.Joale faele ea CAD e kenngoa ho molaoli oa mochine oa CNC, moo e sebelisetsoang ho hlahisa tsela ea lisebelisoa.Mochini oa CNC ebe o hlophisoa ka lisebelisoa tse loketseng tsa ho itšeha, joalo ka litsila tsa ho qetela tse nang le taemane le li-drill tsa carbide, ebe karolo e kenngoa mochining.Qetellong, mochini oa CNC o sebetsoa ho khaola karolo ho latela tsela ea sesebelisoa e hlahisitsoeng.CNC machining ea li-ceramics hangata e sebelisoa ho theha lijeometri tse rarahaneng, joalo ka li-implants tsa bongaka, likarolo tsa elektroniki, le li-blade tsa turbine.

Ke likarolo life tsa machining tsa CNC tse ka li sebelisang bakeng sa lirafshoa

Likarolo tsa machining tsa CNC bakeng sa li-ceramics hangata li kenyelletsa li-cutters, li-mill, li-drill, li-routers, lisakha le lisila.Lisebelisoa tse ling tse sebelisoang bakeng sa machining a CNC a lirafshoa li kenyelletsa li-cutter tse hlabang, li-seha tsa litaemane, le lipholishe tsa litaemane.Lisebelisoa tsena li sebelisetsoa ho etsa libopeho tse rarahaneng le ho finyella sephetho se nepahetseng ka mefuta e mengata e fapaneng ea likarolo tsa ceramic.

Ke mofuta ofe oa kalafo ea holim'a metsi o loketseng likarolo tsa machining tsa CNC tsa ceramics

Liphekolo tse atileng haholo tsa holim'a lirafshoa tse entsoeng ka mochini oa CNC ke ho bentša, ho qhomisa lehlabathe, le ho tlotsa anodizing.Ho ipapisitse le ts'ebeliso, liphekolo tse ling tse kang ho pola, ho penta le ho roala phofo le tsona li ka sebelisoa.

Likarolo tsa machining tsa CNC tse ka sebelisoang bakeng sa li-ceramics tsa machining tsa CNC li kenyelletsa li-mill, li-routers, li-drill, li-mill tsa chamfer le likotoana tsa ho phunya.