Ho forging ke eng?

Forging e bolela mokhoa oa ho etsa tšepe (kapa lisebelisoa tse ling) ka ho e futhumatsa mocheso o phahameng ebe o e otla ka hamore kapa ho e hatella hore e be sebopeho se batlang. Mokhoa oa ho qhekella hangata o sebelisoa ho theha lintho tse matla le tse tšoarellang, joalo ka lisebelisoa, libetsa le likarolo tsa mochini. Tšepe e futhumatsoa ho fihlela e e-ba bonolo 'me e bonolo, ebe e behoa holim'a anvil le ho bōptjoa ka hamore kapa khatiso.

Mefuta ea ho haha

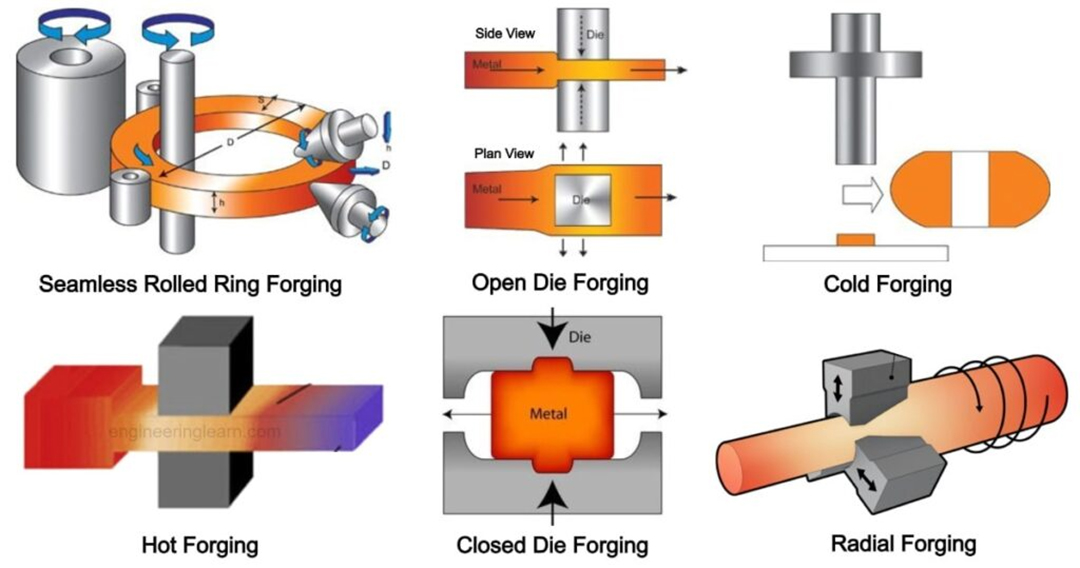

Forging ke ts'ebetso ea ho etsa tšepe eo ho eona ho futhumatsoang thepa ea tšepe ho boemo ba polasetiki 'me ho sebelisoa matla ho e holofatsa hore e be sebopeho se lakatsehang. Ho latela mekhoa e fapaneng ea ho arola, forging e ka aroloa ka mefuta e fapaneng, e latelang ke mekhoa e meng e tloaelehileng ea ho arola:

- Ho ea ka boemo ba tšepe nakong ea ts'ebetso ea ho forging, forging e ka aroloa ka mefuta e latelang:

Cold forging: Cold forging ke mokhoa oa ts'ebetso oa tšepe oa ho sebetsana le stock ea bar le ho e petetsa ka har'a lefu le bulehileng. Mokhoa ona hlaha atambient mocheso kapa ka tlaase ho tšepe recrystallization mocheso ho theha tšepe ka sebopeho batlang.

Hot forging: Ho futhumatsa lisebelisoa tsa tšepe mocheso o itseng ho li etsa polasetiki e ngata, ebe li etsa hammering, extrusion le ts'ebetso e 'ngoe.

Mofuthu oa ho qhekella: Pakeng tsa ho fereka ha serame le ho chesa ho chesa, thepa ea tšepe e futhumatsoa mocheso o tlase ho etsa hore ho be bonolo ho etsoa polasetiki, ebe ho etsoa hamore, extruded le mekhoa e meng.

- Ho latela mekhoa e fapaneng ea ho qhekella, forging e ka aroloa ka mefuta e latelang:

Free forging: eo hape e tsejoang e le ho forging hamore ea mahala, ke mokhoa oa ho hamore le ho ntša tšepe ka ho oa mahala hoa hlooho ea hamore mochining oa forging.

Die forging: Mokgoa wa ho bopa lesela la tshepe ka ho le toboketsa ka hara dae ka ho sebedisa tshepe e itseng.

Precision forging: mokhoa oa ho qhekella bakeng sa ho etsa likarolo tse nang le boleng bo holimo le litlhoko tsa boleng bo holimo.

Ho theha polasetiki: Ho kenyelletsa ho phutha, ho otlolla, ho hatakela, ho taka ka botebo le mekhoa e meng ea ho etsa, e boetse e nkuoa e le mokhoa oa ho etsa.

- Ho ea ka lisebelisoa tse fapaneng tsa forging, forging e ka aroloa ka mefuta e latelang:

Brass forging: e bua ka lits'ebetso tse fapaneng tsa ho qhekella ka koporo le lisebelisoa tsa eona.

Aluminium alloy forging: e bua ka mekhoa e fapaneng ea ho qhekella bakeng sa aluminium le lisebelisoa tsa eona.

Titanium alloy forging: e bua ka mekhoa e fapaneng ea ho qhekella bakeng sa titanium le li-alloys tsa eona.

Ho etsa tšepe e sa hloekang: ho bolela mekhoa e fapaneng ea ho qhekella bakeng sa tšepe e sa hloekang le lisebelisoa tsa eona.

- Ho ea ka libopeho tse fapaneng tsa forging, forging e ka aroloa ka mefuta e latelang:

Flat forging/ Ketso ya ho hatella: ho hatella thepa ya tshepe hore e be sebopeho se bataletseng ho ya ka botenya le bophara bo itseng.

Cone Forging: Ho hatella sesebediswa sa tshepe hore se be le sebopeho sa conical.

Ho kobeha: ho etsa tshepe sebopehong se batloang ka ho kobeha.

Ring forging: Ho etsa lesela la tshepe hore le be sebopeho sa reng.

- Ho ea ka khatello e fapaneng ea ho qhekella, forging e ka aroloa ka mefuta e latelang:

Stamping: Ho sebetsa ha tšepe tlas'a khatello e tlaase, hangata e loketseng bakeng sa tlhahiso ea likarolo tse tšesaane tsa tšepe.

Mekhatello e mahareng: E hloka khatello e kholo ho feta ho hatakela 'me hangata e loketse ho hlahisa likarolo tsa botenya bo mahareng.

High Pressure Forging: Forging e hloka khatello e ngata 'me hangata e loketse ho hlahisa likarolo tse teteaneng.

- Ho ea ka lisebelisoa tse fapaneng tsa forging, forging e ka aroloa ka mefuta e latelang:

Ho etsa likarolo tsa likoloi: Etsa likarolo tse fapaneng tse hlokang ho sebelisoa likoloing, joalo ka likarolo tsa enjene, likarolo tsa chassis, jj.

Aerospace forging: likarolo tse hlokahalang bakeng sa ho etsa lifofane, lirokete le lisebelisoa tse ling tsa sefofane.

Energy Forging: Ho etsa likarolo tse hlokahalang lisebelisoa tse fapaneng tsa matla, joalo ka liboilers, li-turbine tsa khase, jj.

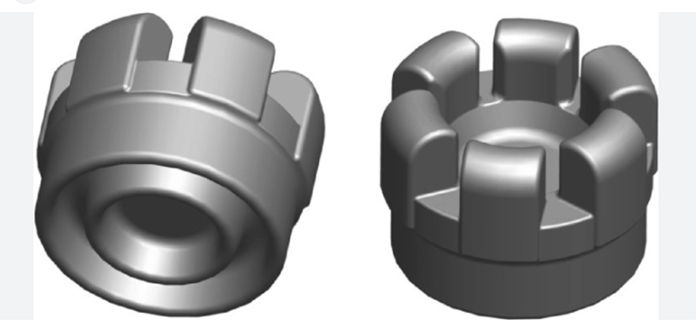

Mechini ea forging: Ho etsa likarolo tse hlokang ho sebelisoa lisebelisoa tse fapaneng tsa mochini, joalo ka li-bearing, likere, lithupa tse hokelang, jj.

1. Matla a ntlafetseng le ho tšoarella nako e telele:Ho forging ho ka ntlafatsa lisebelisoa tsa tšepe, ho etsa hore e be matla le ho tšoarella.

2. Popeho e nepahetseng:Forging e lumella hore tšepe e bōpe ka nepo, e leng ea bohlokoa ha ho etsoa likarolo tse nang le libopeho le boholo bo itseng.

3. Lintho tse ntlafalitsoeng:Mokhoa oa ho qhekella o ka ntlafatsa thepa ea tšepe ea tšepe, joalo ka ho hanyetsa kutu le ho hanyetsa ho roala, ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokang.

4. Litšila tse fokolitsoeng:Ha ho bapisoa le mekhoa e meng ea ho sebetsa ka tšepe, ho qapa ho hlahisa litšila tse fokolang 'me ho lumella tšebeliso e ntle ea thepa, e ka thusang ho fokotsa litšenyehelo.

5. Qetello e ntlafalitsoeng ea bokaholimo:Ho qhekella ho ka fella ka hore ho be le boreleli holim'a metsi, e leng ntho ea bohlokoa bakeng sa likarolo tse hlokang ho kopana kapa ho thella khahlanong le tse ling.

6. Keketseho ea katleho ea tlhahiso:Ka tsoelo-pele ea theknoloji ea ho theha, ts'ebetso e se e potlakile ebile e sebetsa hantle, e lumellang tlhahiso e eketsehileng ea tlhahiso.