Bokhoni ba rona ba ho fetola litšebeletso tsa CNC

From prototyping to full production runs. Our wide range of CNC lathes and turning centers will allow you to produce highly accurate, high quality parts to meet even your most complex requirements. Can’t decide which machining process is best for you? Just send us drawing by email:rfq@lairun.com.cn

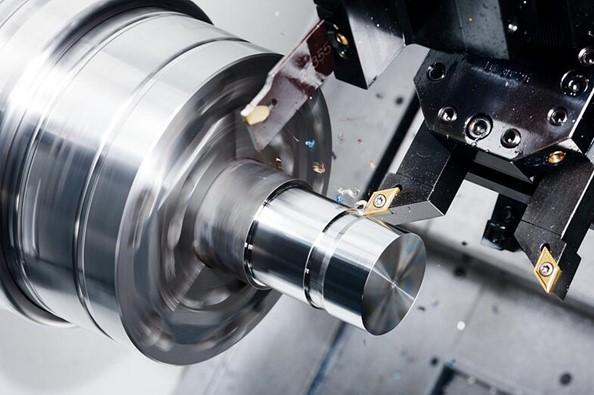

CNC lathe

Mechini e fetolang CNC e khona ho fana ka likarolo tse theko e tlase bakeng sa li-geometri tse bonolo tsa cylindrical. Ts'ebetso ea rona ea ho fetola CNC e hlahisa li-prototypes tsa tloaelo le likarolo tsa tlhahiso ea ts'ebeliso ea ho qetela ka potlako joalo ka letsatsi le le leng. Re sebelisa CNC lathe e nang le lisebelisoa tse phelang e le hore likarolo tse kang likoti tsa axial le radial, flats, grooves, le slots li ka etsoa ka mochine.

Hangata ho fetola CNC ho sebelisoa bakeng sa:

Li-prototype tse sebetsang le likarolo tse sebelisoang qetellong

Likarolo tse nang le likarolo tsa cylindrical

Likarolo tse nang le masoba a axial le radial, flats, grooves, le slots

Likarolo tse nang le li-shafts, li-valve, li-Lock Rings le cylinder.

Re fana ka maikutlo a potlakileng ho netefatsa hore karolo ea hau e ntlafalitsoe bakeng sa ts'ebetso ea ho fetola CNC 'me e lumellana le litlhoko tseo u li hlokang. Moetsi oa rona a ka fana ka likarolo tsa boleng bo holimo tsa tšepe le polasetiki ea CNC bakeng sa prototyping e potlakileng. wer le lebelo bokgoni tse amang mefuta ea likarolo tse ka etsoang ka moruo ho eona.

CNC Turning ke eng? E Sebetsa Joang?

●Computer Numerical Control (CNC) turning ke mokhoa oa tlhahiso o sebelisang lathe ho etsa likarolo tse nepahetseng, tse iketselitsoeng ho tsoa linthong tse fapaneng, joalo ka tšepe, polasetiki le aluminium. Mochini oa lathe o ohla mosebetsi ha sesebelisoa sa ho seha se o etsa ka boholo le sebopeho se lakatsehang.

● Mokhoa oa ho fetola CNC o qala ka moralo o entsoeng ka software ea Computer-Aided Design (CAD). Moralo o fetoloa khoutu eo lathe ea CNC e ka e balang le ho e latela. Opereishene e theha mochine ka ho kenya mochine oa ho sebetsa ka har'a lathe le ho kenya lisebelisoa tse hlokahalang.

● Hang ha mochine o se o lokile, lenaneo la CNC le laeloa, 'me opareitara e qala ts'ebetso. CNC lathe e phunya sesebediswa sa mosebetsi ka lebelo le phahameng ha sesebelisoa sa ho itšeha se ntse se tsamaea ka thepa, se tlosa lisebelisoa tse feteletseng ho fihlela karolo e fihla sebopeho le boholo bo lakatsehang.

●CNC turning e fana ka melemo e mengata ho feta tloaelo ea ho fetola ka matsoho. Ntlha ea pele, ho nepahala le ho nepahala ha ho fetoha ha CNC ho phahame haholo ho feta ho fetola ka letsoho. Lebaka ke hore mochini oa CNC o hlophiselitsoe ho latela moralo hantle, athe ho fetola ka letsoho ho ipapisitse le boiphihlelo le boiphihlelo ba opareitara.

● Ho ekelletsa moo, ho phethola CNC ho potlakile ho feta ho fetola ka letsoho. Ka lathe ea CNC, opareitara e ka theha le ho tsamaisa likarolo tse ngata ka nako e le 'ngoe, e leng se hlahisang sekhahla sa tlhahiso e phahameng haholo. Ho fetola CNC ho boetse ho sebetsa hantle haholo, ho na le litšila tse fokolang tsa thepa le litšenyehelo tse tlase tsa basebetsi.

● Lebenkeleng la rona la mochine oa CNC, re fana ka litšebeletso tsa boleng bo phahameng ba ho fetola CNC ka potlako. Lisebelisoa tsa rona tsa morao-rao le basebetsi ba nang le phihlelo ba re lumella ho etsa likarolo tse tloaelehileng ka ho nepahala le ho potlaka ho ikhethang. Re sebetsa ka ho khetheha ho prototyping 'me re khona ho sebetsana le lihlahisoa tse nyane le tse kholo.

● Qetellong, ho fetola CNC ke mokhoa o sebetsang hantle haholo le o nepahetseng oa tlhahiso o ka hlahisang likarolo tse tloaelehileng ka potlako le ka ho nepahala ho ikhethang. Hore na o hloka prototype e le 'ngoe kapa tlhahiso e kholo ea tlhahiso, CNC turning ke khetho e ntle bakeng sa litlhoko tsa hau tsa tlhahiso.

Mefuta ea CNC Lathes

Ho na le mefuta e mengata ea likhoele, empa tse atileng haholo ke likhoele tsa 2-axis CNC le li-lathe tsa mofuta oa Switzerland. Li-lathes tsa mofuta oa Switzerland li ikhethile ka hore thepa ea thepa e feptjoa ka bushing ea tataiso, e lumellang sesebelisoa hore se sehe haufi le ntlha ea tšehetso, e leng se etsang hore e be molemo ka ho khetheha bakeng sa likarolo tse telele, tse tšesaane tsa CNC lathe le micromachining. Li-lathe tse ling tsa mofuta oa Switzerland le tsona li tla li na le hlooho ea sesebelisoa sa bobeli se sebetsang joalo kaMohaho oa CNC, e ba lumellang ho etsa mesebetsi e mengata ea machining ntle le hore ba tsamaise workpiece ho mochine o fapaneng. Sena se etsa hore masela a mofuta oa Switzerland a be le litšenyehelo tse ngata bakeng sa likarolo tse rarahaneng tse fetoletsoeng ka lits'ebeletso tsa CNC tsa lathe.

Mefuta ea CNC Lathes

Joalo kaLisebelisoa tsa CNC, Li-lathe tsa CNC li ka behoa habonolo bakeng sa ho pheta-pheta ho phahameng, e leng se etsang hore e be tse ntle bakeng sa ntho e 'ngoe le e' ngoe ho tloha ho prototyping e potlakileng ho ea ho tlhahiso e tlaase le e phahameng. Litsi tsa ho fetola CNC tse nang le li-multi-axis le li-lathes tsa mofuta oa Switzerland li lumella ho sebetsa ka makhetlo a mangata mochineng o le mong. ho ba etsa khetho e theko e tlaase bakeng sa li-geometri tse rarahaneng tse neng li ka hloka mechine e mengata kapa liphetoho tsa lisebelisoa leloaleng la setso la CNC.

Mefuta ea CNC Lathes

●Haeba o hloka boleng bo holimo, likarolo tsa tloaelo kapele, lits'ebeletso tsa rona tsa ho fetola CNC ke khetho e ntle haholo. Lebenkeleng la rona la mochini oa CNC, re sebelisa lisebelisoa tsa morao-rao le basebetsi ba nang le boiphihlelo ho etsa likarolo tse nepahetseng ka lebelo le ikhethang le ho nepahala.

● Litšebeletso tsa rona tsa ho fetola CNC ka potlako li loketse bakeng sa prototyping le tlhahiso ea tlhahiso e tlaase ho ea bohareng. Re ipapisitse le ho theha likarolo tse ikhethileng ho tsoa lisebelisoa tse fapaneng, ho kenyeletsoa tšepe, polasetiki le lehong. Re fana ka mefuta e mengata ea ho qetela, ho kenyelletsa le aluminium ea anodized le PTFE.

● Ts'ebetso ea rona ea ho fetola CNC e qala ka moralo o entsoeng ka software ea CAD. Moralo o fetoloa khoutu eo lathe ea CNC e ka e balang le ho e latela. Opereishene e theha mochine ka ho kenya mochine oa ho sebetsa ka har'a lathe le ho kenya lisebelisoa tse hlokahalang.

● Hang ha mochine o se o lokile, opareitara e qala tšebetso. CNC lathe e phunya sesebediswa sa mosebetsi ka lebelo le phahameng ha sesebelisoa sa ho itšeha se ntse se tsamaea ka thepa, se tlosa lisebelisoa tse feteletseng ho fihlela karolo e fihla sebopeho le boholo bo lakatsehang.

● Litšebeletso tsa rona tsa ho fetola CNC ka potlako li fana ka melemo e mengata. Ntlha ea pele, re ka hlahisa likarolo tse tloaelehileng ka potlako, ka nako e khutšoanyane haholo ea ho etella pele ho feta mekhoa e tloaelehileng ea tlhahiso. Ho feta moo, ho nepahala le ho nepahala ha rona ha ho bapisoe, ka lebaka la lisebelisoa tsa rona tsa morao-rao le basebetsi ba nang le boiphihlelo.

● Re boetse re fana ka litšebeletso tse ntle tsa bareki le tšehetso nakong eohle ea ts'ebetso. Ho tloha ho moralo ho isa ho phano, re sebetsa haufi-ufi le bareki ba rona ho netefatsa hore ba fumana likarolo tsa boleng bo holimo ka nako e khuts'oane.

Qetellong, lits'ebeletso tsa rona tsa boleng bo holimo tsa ho fetola CNC ke khetho e ntle bakeng sa litlhoko tsa hau tsa tlhahiso. Hore na o hloka prototype e le 'ngoe kapa tlhahiso e kholo ea tlhahiso, re ka fana ka likarolo tsa tloaelo kapele le ka nepo e ikhethang.

Bokhoni bo phahameng ba ho fetola CNC

| Meeli ea boholo ba karolo | Diyuniti tsa metric | Lihlopha tsa Imperial |

| Boholo ba bophara ba karolo | 431 limilimithara | 17 ho |

| Boholo ba bolelele ba karolo | 990 limilimithara | 39 ka |

| Boholo ba ho sisinyeha holim'a lekareche | 350 limilimithara | 13.7 ka hare |

| Boholo ba spindle ka lesoba | 40 limilimithara | 1.5 ka hare |

Ho roala ka phofo

Mona ke lethathamo la lisebelisoa tsa rona tse tloaelehileng tsa mochini oa CNC tse fumanehang.

Litšepe tsa CNC

| Plastiki | Plastiki e Matlafalitsoeng |

| ABS | Garolite G-10 |

| Polypropylene (PP) | Polypropylene (PP) 30% GF |

| Nylon 6 (PA6 /PA66) | Nylon 30% GF |

| Delrin (POM-H) | FR-4 |

| Acetal (POM-C) | PMMA (Akriliki) |

| PVC | PEKE |

| HDPE | |

| UHMW PE | |

| Polycarbonate (PC) | |

| PET | |

| PTFE (Teflon) |

Mamello

Re latela litekanyetso tsa ISO 2768 tsa CNC Machining.

| Meeli ea boholo ba lebitso | Plastiki (ISO 2768- m) | Litšepe (ISO 2768- f) |

| 0.5mm * ho isa ho 3mm | ±0.1mm | ± 0.05 limilimithara |

| Ho tloha ho 3 ho isa ho 6 mm | ±0.1mm | ± 0.05 limilimithara |

| Ho tloha ho 6 ho isa ho 30 mm | ± 0.2mm | ±0.1mm |

| Ho feta 30mm ho isa ho 120mm | ± 0.3 limilimithara | ± 0.15 limilimithara |

| Ho feta 120mm ho 400mm | ± 0.5 limilimithara | ± 0.2mm |

| Ho feta 400mm ho 1000mm | ± 0.8mm | ± 0.3 limilimithara |

| Ho feta 1000mm ho 2000mm | ± 1.2mm | ± 0.5 limilimithara |

| Ho feta 2000mm ho 4000mm | ± 2 limilimithara |

- Ka kopo, bontša ka ho hlaka mamello ea boholo bo ka tlase ho 0.5mm setšoantšong sa hau sa tekheniki.

Litaelo tsa ho fetolela CNC

Tafole e ka tlase e akaretsa litekanyetso tse khothalelitsoeng le tse ka khonehang tsa tekheniki bakeng sa likarolo tse atileng tse fumanehang likarolong tse entsoeng ka mochini oa CNC.

| Sebopeho | Boholo bo khothalelitsoeng | Boholo bo ka khonehang |

| Min. boholo ba sebopeho | Ø 2.5 limilimithara | Ø 0.5 limilimithara |

| Mathoko a ka hare | R8 limilimithara | R 0,25 limilimithara |

| Botenya bo fokolang ba lebota | 0.8 mm (bakeng sa litšepe) | 0.5 mm (bakeng sa litšepe) |

| 1.5 mm (bakeng sa polasetiki) | 1.0 mm (bakeng sa polasetiki) | |

| Likoti | Diameter:Litekanyo tse tloaelehileng tsa ho cheka | Bophara: Ø 0.5 mm |

| Botebo: 4 x bophara | Botebo: 10 x bophara | |

| Likhoele | Boholo: M6 kapa ho feta | Boholo: M2 |

| Bolelele: 3 x bophara |