CNC Milling ke eng?

CNC milling ke mokhoa oa tlhahiso o sebelisetsoang ho hlahisa likarolo tse entsoeng ka mokhoa o ikhethileng ho tsoa ho lisebelisoa tse fapaneng tse kang aluminium, tšepe le polasetiki. Mokhoa ona o sebelisa mechine e laoloang ke k'homphieutha ho etsa likarolo tse rarahaneng tseo ho leng thata ho li hlahisa ho sebelisoa mekhoa e tloaelehileng ea ho etsa mechine. Mechini ea ho sila ea CNC e sebelisoa ke software ea khomphutha e laolang motsamao oa lisebelisoa tsa ho seha, e ba nolofalletsang ho tlosa thepa ho tsoa mosebetsing ho etsa sebopeho le boholo bo lakatsehang.

CNC milling e fana ka melemo e mengata ho feta mekhoa ea setso ea ho sila. E potlakile, e nepahetse, 'me e khona ho hlahisa lijeometri tse rarahaneng tseo ho leng thata ho li etsa ho sebelisoa mechini ea matsoho kapa e tloaelehileng. Tšebeliso ea software ea computer-aid design (CAD) e lumella baqapi ho etsa mehlala e nang le lintlha tse ngata tsa likarolo tse ka fetoleloang habonolo ka khoutu ea mochine hore mochine oa CNC oa ho sila o latele.

Mechini ea ho sila ea CNC e sebetsa ka mokhoa o fapaneng haholo 'me e ka sebelisoa ho hlahisa likarolo tse ngata, ho tloha ho li-brackets tse bonolo ho ea ho likarolo tse rarahaneng bakeng sa lisebelisoa tsa sefofane le tsa bongaka. Li ka sebelisoa ho hlahisa likarolo ka bongata bo fokolang, hammoho le lihlahisoa tse kholo tsa tlhahiso.

3-axis le 3+2-axis CNC milling

Mechini ea ho sila ea 3-axis le 3+2 axis CNC e na le litšenyehelo tse tlase haholo tsa ho qala mochini. Li sebelisetsoa ho hlahisa likarolo tse nang le li-geometri tse batlang li le bonolo.

Boholo ba boholo ba karolo bakeng sa 3-axis le 3+2-axis CNC milling

| Boholo | Diyuniti tsa metric | Lihlopha tsa Imperial |

| Max. karolo ea boholo ba litšepe tse bonolo [1] & li-plastiki | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. karolo ea litšepe tse thata [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. boholo ba sebopeho | Ø 0.50 limilimithara | Ø 0.019 in |

[1] : Aluminium, koporo le koporo

[2] : Tšepe e sa hloekang, tšepe ea sesebelisoa, tšepe ea motsoako le tšepe e bonolo

Tšebeletso ea ho Milling ea boleng bo holimo ea CNC

Ts'ebeletso ea boleng bo holimo e potlakileng ea CNC ke ts'ebetso ea tlhahiso e fang bareki linako tse potlakileng tsa ho fetola likarolo tsa bona tsa tloaelo. Mokhoa ona o sebelisa mechini e laoloang ke komporo ho hlahisa likarolo tse nepahetseng haholo ho tsoa linthong tse fapaneng tse kang aluminium, tšepe le lipolasetiki.

Lebenkeleng la rona la mochini oa CNC, re ipabola ka ho fana ka lits'ebeletso tsa boleng bo holimo tse potlakileng tsa CNC ho bareki ba rona. Mechini ea rona ea morao-rao e khona ho hlahisa likarolo tse rarahaneng ka ho nepahala le lebelo le ikhethang, e leng se etsang hore re be mohloli oa ho ea ho bareki ba hlokang linako tse potlakileng tsa phetoho.

Re sebetsa ka mefuta e fapaneng ea thepa, ho kenyeletsoa anodized aluminium le PTFE, 'me re ka fana ka mefuta e mengata ea ho qetela, ho kenyelletsa le aluminium anodizing. Litšebeletso tsa rona tse potlakileng tsa prototyping li re lumella ho theha le ho lekola likarolo kapele, ho netefatsa hore bareki ba rona ba fumana lihlahisoa tsa boleng bo holimo ka nako e khuts'oane e ka khonehang.

Kamoo CNC Milling e Sebetsang Kateng

CNC milling e sebetsa ka ho sebelisa mechine e laoloang ke k'homphieutha ho tlosa thepa ho tloha mosebetsing ho etsa sebopeho kapa moralo o itseng. Mokhoa ona o kenyelletsa lisebelisoa tse ngata tsa ho itšeha tse sebelisetsoang ho tlosa thepa ho tloha mosebetsing ho etsa sebopeho le boholo bo lakatsehang.

Mochini oa ho sila oa CNC o sebelisoa ke software ea komporo e laolang motsamao oa lisebelisoa tsa ho itšeha. Software e bala litlhaloso tsa moralo oa karolo ebe e li fetolela ho khoutu ea mochini eo mochini oa CNC o e latelang. Lisebelisoa tsa ho itšeha li tsamaea ka lilepe tse ngata, li li lumella ho hlahisa li-geometri le libopeho tse rarahaneng.

Ts'ebetso ea ho sila ea CNC e ka sebelisoa ho theha likarolo ho tsoa ho lisebelisoa tse fapaneng, ho kenyeletsoa aluminium, tšepe le polasetiki. Ts'ebetso e nepahetse haholo ebile e khona ho hlahisa likarolo tse nang le mamello e thata, e etsa hore e be e loketseng bakeng sa tlhahiso ea likarolo tse rarahaneng bakeng sa lisebelisoa tsa sefofane le tsa bongaka..

Mefuta ea CNC Mills

3-Axis

Mofuta o sebelisoang ka ho fetesisa oa mochini o silang oa CNC. Tšebeliso e feletseng ea litsela tsa X, Y, le Z e etsa hore leloala la 3 Axis CNC le be le molemo bakeng sa mesebetsi e mengata e fapaneng.

4-Axis

Mofuta ona oa router o lumella mochine hore o potolohe holim'a axis e otlolohileng, o tsamaisa sesebedisoa sa mosebetsi ho hlahisa machining a tsoelang pele.

5-Axis

Mechini ena e na le lilepe tse tharo tsa setso hammoho le lilepe tse ling tse peli tse rotary. Ka hona, router ea 5-axis CNC e khona ho kenya mahlakoreng a 5 a sesebelisoa mochining o le mong ntle le ho tlosa mochini oa ho sebetsa le ho seta bocha. Sebaka sa mosebetsi sea potoloha, 'me hlooho ea spindle e khona ho potoloha le sengoathoana. Tsena li kholo ebile li theko e boima.

Ho na le liphekolo tse 'maloa tse ka sebelisoang bakeng sa likarolo tsa aluminium tsa CNC. Mofuta oa phekolo o sebelisoang o tla itšetleha ka litlhoko tse khethehileng tsa karolo le qetello e lakatsehang. Mona ke tse ling tsa liphekolo tse tloaelehileng tsa holim'a likarolo tsa aluminium tsa CNC:

Melemo e meng ea Mekhoa ea Machining ea CNC Mill

Mechini ea ho sila ea CNC e hahiloe bakeng sa tlhahiso e nepahetseng le e pheta-phetoang e etsang hore e phethahale bakeng sa prototyping e potlakileng le tlhahiso ea molumo o tlase ho isa holimo. Li-mill tsa CNC le tsona li ka sebetsa ka mefuta e fapaneng ea lisebelisoa ho tloha ho aluminium ea mantlha le lipolasetiki ho isa ho tse sa tloaelehang joalo ka titanium - ho li etsa mochini o loketseng mosebetsi ofe kapa ofe.

Lisebelisoa tse fumanehang bakeng sa machining CNC

Mona ke lethathamo la lisebelisoa tsa rona tse tloaelehileng tsa mochini oa CNC tse fumanehangintsa ronalebenkele la mochini.

| Aluminium | Ts'epe e sa beng le mabali | Bonolo, Alloy & Tool steel | Tšepe e 'ngoe |

| Aluminium 6061-T6 / 3.3211 | SUS303 /1.4305 | Tšepe e bonolo 1018 | Brass C360 |

| Aluminium 6082 / 3.2315 | SUS304L /1.4306 | Koporo C101 | |

| Aluminium 7075-T6 / 3.4365 | 316L /1.4404 | Tšepe e bonolo 1045 | Koporo C110 |

| Aluminium 5083 /3.3547 | 2205 Duplex | Alloy tšepe 1215 | Sehlopha sa 1 sa Titanium |

| Aluminium 5052 / 3.3523 | Tšepe e sa hloekang 17-4 | Tšepe e bonolo ea A36 | Sehlopha sa 2 sa Titanium |

| Aluminium 7050-T7451 | Tšepe e sa hloekang 15-5 | Alloy tšepe 4130 | Invar |

| Aluminium 2014 | Sebetsa 416 | Alloy tšepe 4140 / 1.7225 | Tlhaloso: 718 |

| Aluminium 2017 | Sebetsa 420 /1.4028 | Alloy tšepe 4340 | Magnesium AZ31B |

| Aluminium 2024-T3 | Sebetsa 430 /1.4104 | Sesebelisoa sa tšepe A2 | Brass C260 |

| Aluminium 6063-T5 / | Sebetsa 440C /1.4112 | Sesebelisoa sa tšepe A3 | |

| Aluminium A380 | Sebetsa 301 | Sesebelisoa sa tšepe D2 / 1.2379 | |

| Aluminium MIC 6 | Sesebelisoa sa tšepe S7 | ||

| Sesebelisoa sa tšepe H13 |

Plastiki ea CNC

| Plastiki | Plastiki e Matlafalitsoeng |

| ABS | Garolite G-10 |

| Polypropylene (PP) | Polypropylene (PP) 30% GF |

| Nylon 6 (PA6 /PA66) | Nylon 30% GF |

| Delrin (POM-H) | FR-4 |

| Acetal (POM-C) | PMMA (Akriliki) |

| PVC | PEKE |

| HDPE | |

| UHMW PE | |

| Polycarbonate (PC) | |

| PET | |

| PTFE (Teflon) |

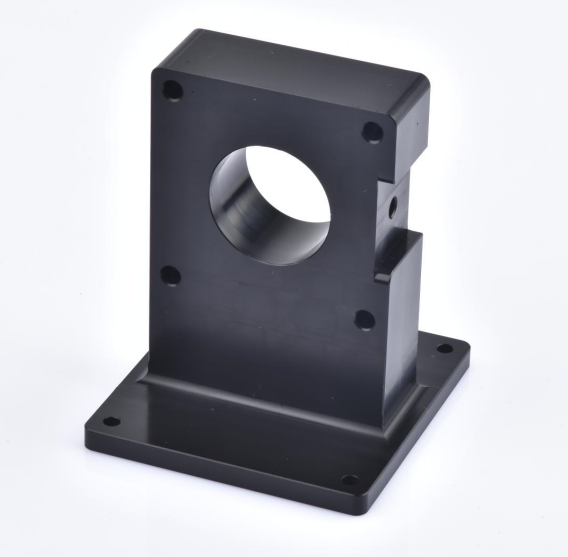

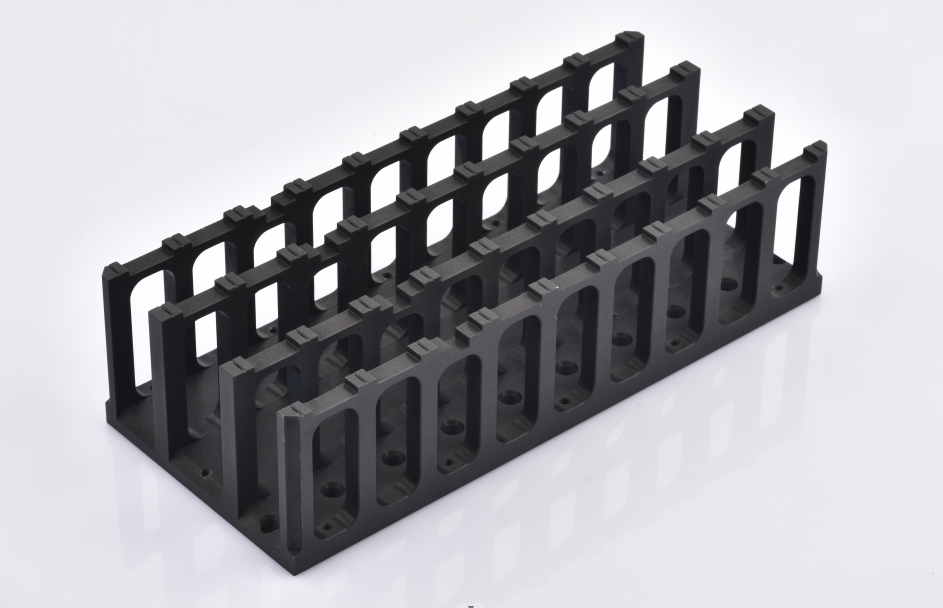

Gallery ea likarolo tsa mochini oa CNC

Re etsa li-prototypes tse potlakileng le litaelo tsa tlhahiso ea boleng bo tlase bakeng sa bareki ba liindasteri tse ngata: sefofane, likoloi, ts'ireletso, lisebelisoa tsa elektroniki, li-hardware tse qalang, li-automation tsa indasteri, mechini, tlhahiso, lisebelisoa tsa bongaka, oli & khase le liroboto.