Ho na le liphekolo tse 'maloa tse ka sebelisoang bakeng sa likarolo tsa aluminium tsa CNC.Mofuta oa phekolo o sebelisoang o tla itšetleha ka litlhoko tse khethehileng tsa karolo le qetello e lakatsehang.Mona ke tse ling tsa liphekolo tse tloaelehileng tsa holim'a likarolo tsa aluminium tsa CNC:

1. Anodizing / Hard anodized

Ena ke ts'ebetso eo ho eona ho lengoang lesela la oxide holim'a aluminium.Anodizing e ka fana ka qetello e tšoarellang, e sa bolaeeng ke kutu e ka dauoang ka mebala e fapaneng. E ka ba e hlakileng, e ntšo, e khubelu, e putsoa, e pherese, e mosehla kapa mebala efe kapa efe eo u e hlokang ho latela moralo oa hau.

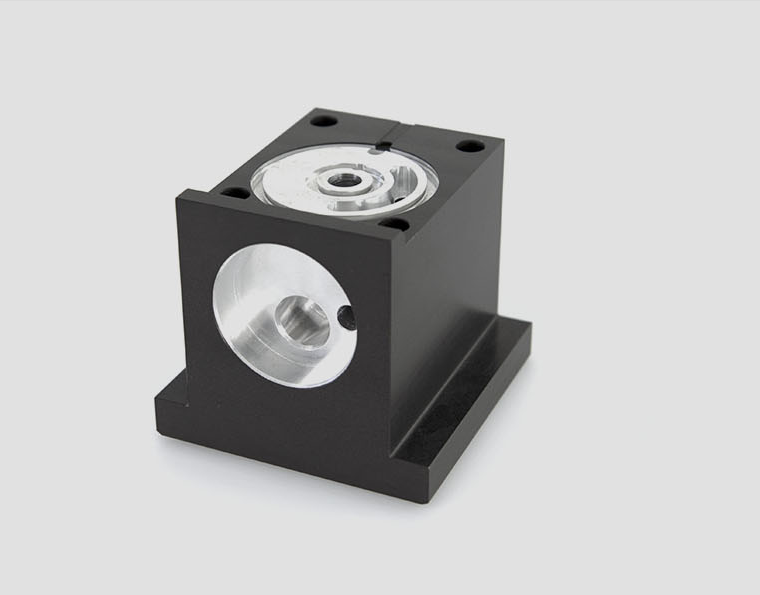

2. ALTEF (Teflon)

ALTEF(Teflon) ke mofuta oa ts'ebetso ea kalafo ea holim'a metsi e sebelisoang likarolong tse entsoeng ka mochini oa CNC.E emetse Aluminium Teflon Electroless Nickel Plating, mme e kenyelletsa ho beha lesela le lesesaane la nickel e se nang motlakase holim'a karolo ea aluminium, e lateloe ke lera la Teflon.

Tshebetso ea ALTEF e sebelisetsoa ho ntlafatsa ho hanyetsa ho roala le ho fokotsa coefficient ea likhohlano tsa likarolo tsa aluminium.Lera la nickel e se nang motlakase le fana ka sebaka se thata, se thibelang kutu se ntlafatsang ho tšoarella ha karolo, ha Teflon e fokotsa khohlano pakeng tsa karolo le libaka tse ling, ho ntlafatsa thepa ea karolo e thellang.

Ts'ebetso ea ALTEF e sebetsa ka ho qala ka ho hloekisa karolo ea aluminium ho tlosa litšila kapa litšila.Joale karolo e kenngoa ka har'a tharollo e nang le lik'hemik'hale tsa nickel plating tse se nang motlakase, tse kenyang lesela la nickel holim'a karolo ka mokhoa oa autocatalytic.Botenya ba nickel layer bo ka ba 10-20 microns.

Ka mor'a moo, karolo e kenngoa ka har'a tharollo e nang le likaroloana tsa Teflon, tse khomarelang lera la nickel 'me li etsa lera le lesesaane, le tšoanang la Teflon holim'a karolo.Lera la Teflon hangata le pota-potile li-microns tse 2-4.

Sephetho sa ts'ebetso ea ALTEF ke sebaka se sa sebetseng haholo le se nang le likhohlano tse tlase karolong ea aluminium, e loketseng ho sebelisoa lits'ebetsong tse phahameng le tse nepahetseng, joalo ka liindasteri tsa sefofane, likoloi le tsa bongaka.

3. Ho roala ha phofo

Ena ke ts'ebetso eo ho eona phofo e omeletseng e sebelisoang ka mokhoa oa electrostatically holim'a aluminiamo ebe e behoa ho etsa qetello e tšoarellang, e khabisitsoeng.

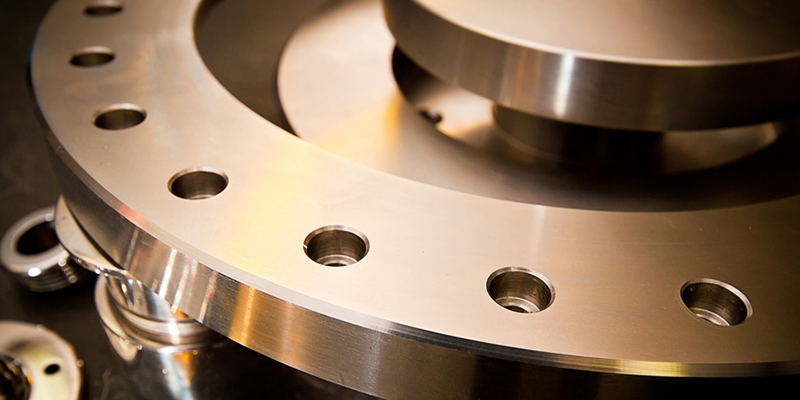

4. Ho Pholisa Lik'hemik'hale

Mokhoa ona o sebelisa lik'hemik'hale ho tlosa thepa e nyenyane holim'a aluminium ho etsa qetello e boreleli, e benyang.

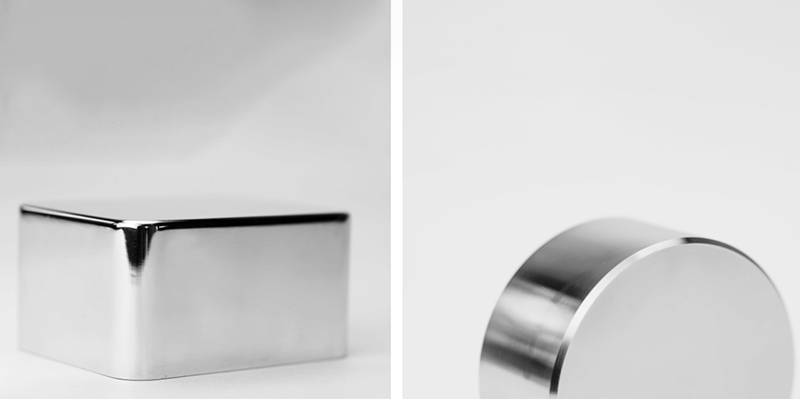

5. Mechanical polishing

Ts'ebetso ena e kenyelletsa ho sebelisa letoto la li-abrasives ho tlosa thepa holim'a aluminium ho etsa qetello e boreleli, e benyang.

6. Ho qhomisa lehlabathe

Ts'ebetso ena e kenyelletsa ho sebelisa moea o nang le khatello e phahameng kapa metsi ho phatlola lehlabathe kapa lisebelisoa tse ling tse hoholang holim'a aluminiamo ho etsa mophetho o hlophisitsoeng.