Sebakeng sa kajeno sa tlholisano ea tlhahiso,likarolo tsa machining tsa koporo tsa CNCe bapala karolo ea bohlokoa ho netefatsa ts'ebetso e phahameng, e tšoarellang, le ho nepahala ho pholletsa le liindasteri tse fapaneng. Ka lebaka la ts'ebetso ea eona e ntle haholo, e hanyetsang kutu, le ts'ebetso e ikhethang ea mocheso le motlakase, koporo e fetohile sesebelisoa se ratoang bakeng sa ho hlahisa likarolo tse nepahetseng tse sebelisoang ho elektronike, lipeipi, likoloi, lisebelisoa tsa bongaka le lisebelisoa tsa indasteri.

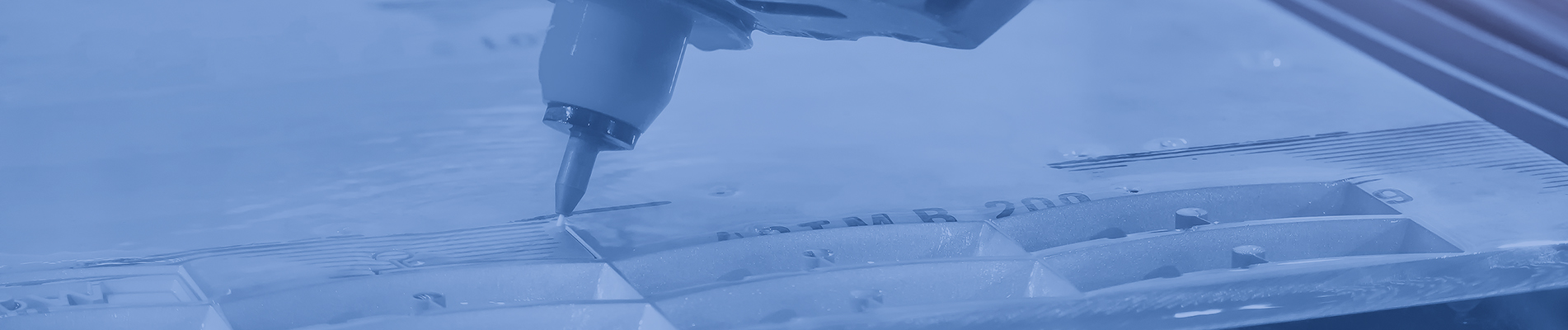

Ho LAIRUN, re motlotlo ka boitseanape ba rona ba ho sebetsa ka nepo ka mochini oa CNC, ho fana ka lisebelisoa tsa boleng bo holimo, tse entsoeng ka tloaelo tse etselitsoeng ho fihlela litlhoko tse ikhethang tsa bareki ba rona. Ea ronamechine ea morao-rao ea CNClitsi li re lumella ho finyella mamello e tiileng, meralo e rarahaneng, le ho qeta holimo ho boreleli, ho etsa bonnete ba hore karolo e 'ngoe le e' ngoe ea koporo e finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le ho tsitsisa. Ebang ke lihokelo tsa brass, li-fittings, bushings, tse kenyang likhoele, kapa likarolo tsa mochini tse nepahetseng, re fana ka litharollo tse matlafatsang ts'epehi ea sehlahisoa le ts'ebetso.

E 'ngoe ea melemo ea mantlha ea mochini oa CNC oa koporo ke ho sebetsa hantle ha eona. Brass ke thepa e lumellang machining a lebelo le phahameng ka ho roala lisebelisoa tse fokolang, ho fokotsa litšenyehelo tsa tlhahiso ha ho ntse ho boloka ho nepahala ho phahameng. Ho feta moo, ho hanyetsa ha eona ka tlhaho ho kutu le mocheso o motle haholo le conductivity ea motlakase ho etsa hore e be khetho e nepahetseng bakeng sa lits'ebetso tse hlokang botsitso le ts'ebetso ea nako e telele.

Ho LAIRUN, re latela ts'ebetso e matla ea taolo ea boleng, re sebelisa lisebelisoa tse tsoetseng pele tsa tlhahlobo le mekhoa e nepahetseng ea mochini ho netefatsa liphetho tse se nang sekoli. Sehlopha sa rona sa boenjiniere se nang le boiphihlelo se sebetsa haufi-ufi le bareki ho tloha ho prototyping ho isa tlhahisong ea bongata, se fana ka litharollo tsa tloaelo tsa machining tse tsamaellanang le litlhaloso tsa bona hantle. Ka boitlamo ba rona ba bokhabane le tsoelopele e tsoelang pele ea thekenoloji, re ikemiselitse ho ba molekane oa hau ea tšepahalang bakeng salikarolo tsa mochini tsa CNC tse sebetsang hantle haholo.

Ha liindasteri li ntse li tsoela pele ho fetoha, tlhokahalo ea likarolo tsa koporo tse sebetsang hantle haholo, tse tšoarellang, le tse sebetsang hantle tsa mochini oa CNC e ntse e le matla. Ikopanye le LAIRUN kajeno ho hlahloba hore na boitseanape ba rona ba mochini oa CNC oa koporo bo ka ts'ehetsa khoebo ea hau joang ka litharollo tsa tlhahiso tsa boleng bo holimo, tse baballang chelete e ngata.

Nako ea poso: Mar-22-2025